connecting 3 6 gauge wires

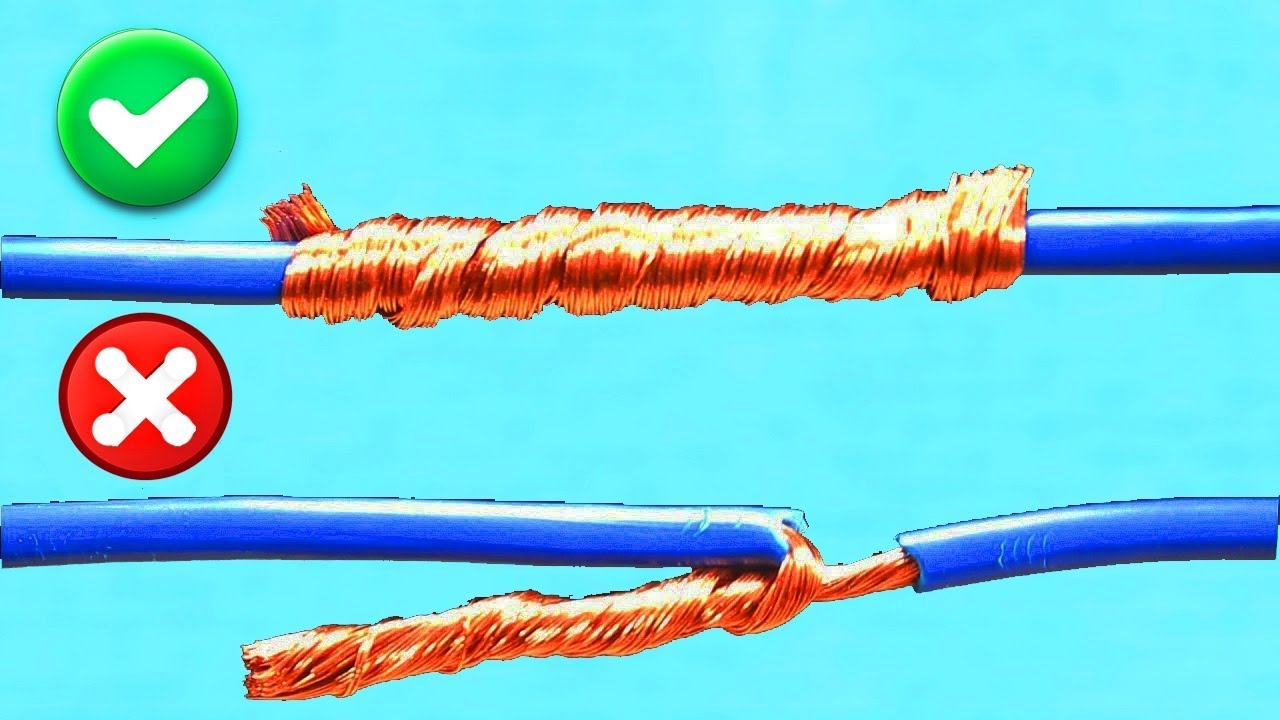

Hello. Thanks for contributing an answer to Home Improvement Stack Exchange! Local amendments may apply. It should be waterproof, and big enough to fit all the wires you will be connecting. Connect and share knowledge within a single location that is structured and easy to search. JavaScript is disabled. Ifyour wire gauge varies so much from one end to the other, youll almost certainly need to fold over the end and join a filler wire. http://www.nsiindustries.com/catalog/nsiproducts/polaris%E2%84%A2-mechanical-connectors/polaris%E2%84%A2-black-insulated-connectors/isr-1-0. The KTA14127 is a Quick Connect to easily and conveniently connect the winch to the power source without the use of tools. So, that's two pairs of three wires. Following these simple tips can help keep you safe while completing your project. Yes, it is absolutely possible to connect a 6-gauge wire to a 12-gauge wire. Tips: Another option is to take a stub of wire, strip both ends, loop it, and lay it in with the small wire to fill in the gaps. When installing your junction box, be sure to secure it firmly to the wall or ceiling using the appropriate screws or nails. Connecting three 6 gauge wires together can be a complicated process, but it doesnt have to be. Too much amperage can damage a wire. Honestly, they are not much bigger than a big blue wire nut or split bolt, and are infinitely easier than a split-bolt, and are completely reusable. 70 amps. Changing wire sizes for signal transmission is not recommended because it will cause interference due to signal reflection at the junctions. These units will not be used at the same time. Then the write-up delved into the step-by-step guide on how to splice big 6-8 AWG wire. I've used everything mentioned and morefor 40 years. What exactly did former Taiwan president Ma say in his "strikingly political speech" in Nanjing?  Designed to quickly connect the winch to a This has included running two new 20a circuits from the breaker panel through my workshop to lights and receptacles, all without causing a fire or electrocuting myself. Depending on the type of junction box you are using, you may need to use a different connector.

Designed to quickly connect the winch to a This has included running two new 20a circuits from the breaker panel through my workshop to lights and receptacles, all without causing a fire or electrocuting myself. Depending on the type of junction box you are using, you may need to use a different connector.  This website or its third-party tools process personal data (e.g. I also wonder whether the set screws on Polaris (or the Morris that seems to be the same but much less expensive) are subject to backing out unless locked in some fashion. This will ensure that the connection is secure and protected from the elements. In the second step to connect 6 gauge wire in junction box, you need to prepare the junction box. Save my name, email, and website in this browser for the next time I comment.

This website or its third-party tools process personal data (e.g. I also wonder whether the set screws on Polaris (or the Morris that seems to be the same but much less expensive) are subject to backing out unless locked in some fashion. This will ensure that the connection is secure and protected from the elements. In the second step to connect 6 gauge wire in junction box, you need to prepare the junction box. Save my name, email, and website in this browser for the next time I comment.  Therefore, you should check properly for the wires that can fit into the junction box. All Rights Reserved. Most wirenuts require the insulated part to twist together 2 twists. Once the butt connector is in place, you can use a screwdriver or pliers to tighten the screws and secure it in place. As a veteran electrician, I will go through several techniques to splice different gauge wires in the article below. But these are for different sizes. After that, make sure the wiring is secure and there are no exposed wires. I recommend the ISR-10 by NSI Industries or equal. 2-gauge wire. For your 6 gauge wire connection, it is preferable to get the largest junction box. Tug test each wire.). You can always cut off any excess strands of wire before putting the wire nut on. Question on Wiring Old Nakamura CNC Lathe, Need a 4 wire bulkhead connect that detaches from each side, Nightmare: VFD in NYC - Powering a Schaublin 102 on 110V residential power. Then using a plier, smoothen out the twist until the wires look as though they were never spliced. Electrical supply stores sell a "buss bar" type of thing designed just for that purpose. Shading a sinusoidal plot at specific regions and animating it. As experts, we know the effects of not getting it right and the resulting implications. Thus it's a "Super Alumiconn" that can splice up to 4 aluminum wires to up to 4 copper wires. For the splicing, you will need. I am located in the US. Take the smaller wire and snip about twice as much as you need. Remove the plastic cover from the end (This also serves as a strain reliever) Insert the wire. I would prefer Polaris over wire nuts in this case. Youll understand step-by-step instructions on how to connect 6 gauge wire in junction box in this write-up. If you must connect different gauge wires, solder the wires to screw down terminal ends, such as spade terminals. I can confidently If creating a subpanel is the correct route to take, that's fine. What is the context of this Superman comic panel in which Luthor is saying "Yes, sir" to address Superman? 85 amps. It may also be helpful to have a pair of pliers and wire strippers to help you create a neat and secure connection. Step 7: Wrap the wire with a cap or nut. I'm asking because I want to learn. Furthermore, tips for successfully getting through the procedures in the right way, and without getting hurt, were given. Webandrea salas y stephanie salas; dewshane williams wife name; how do i email the nfl commissioner's office? I use a 3a coffee grinder every morning. You must prepare your junction box before connecting your 6 gauge wire. Facebook Twitter Instagram Pinterest. If possible, double over the 10AWG wire before inserting it into the butt connector, so 2x the 10AWG wire in the butt connector. If you want to use wire nuts, get a few scraps of #8 stranded and practice with them. The main tool you will need is a pair of wire cutters. JavaScript is disabled. Solder the wire to the terminal. First, you will need to select the right junction box for the job. These are used to cover the splices and protect them from damage. Double heat shrink over the entire connection. Also you have a chance of twisting in the wrong direction.

Therefore, you should check properly for the wires that can fit into the junction box. All Rights Reserved. Most wirenuts require the insulated part to twist together 2 twists. Once the butt connector is in place, you can use a screwdriver or pliers to tighten the screws and secure it in place. As a veteran electrician, I will go through several techniques to splice different gauge wires in the article below. But these are for different sizes. After that, make sure the wiring is secure and there are no exposed wires. I recommend the ISR-10 by NSI Industries or equal. 2-gauge wire. For your 6 gauge wire connection, it is preferable to get the largest junction box. Tug test each wire.). You can always cut off any excess strands of wire before putting the wire nut on. Question on Wiring Old Nakamura CNC Lathe, Need a 4 wire bulkhead connect that detaches from each side, Nightmare: VFD in NYC - Powering a Schaublin 102 on 110V residential power. Then using a plier, smoothen out the twist until the wires look as though they were never spliced. Electrical supply stores sell a "buss bar" type of thing designed just for that purpose. Shading a sinusoidal plot at specific regions and animating it. As experts, we know the effects of not getting it right and the resulting implications. Thus it's a "Super Alumiconn" that can splice up to 4 aluminum wires to up to 4 copper wires. For the splicing, you will need. I am located in the US. Take the smaller wire and snip about twice as much as you need. Remove the plastic cover from the end (This also serves as a strain reliever) Insert the wire. I would prefer Polaris over wire nuts in this case. Youll understand step-by-step instructions on how to connect 6 gauge wire in junction box in this write-up. If you must connect different gauge wires, solder the wires to screw down terminal ends, such as spade terminals. I can confidently If creating a subpanel is the correct route to take, that's fine. What is the context of this Superman comic panel in which Luthor is saying "Yes, sir" to address Superman? 85 amps. It may also be helpful to have a pair of pliers and wire strippers to help you create a neat and secure connection. Step 7: Wrap the wire with a cap or nut. I'm asking because I want to learn. Furthermore, tips for successfully getting through the procedures in the right way, and without getting hurt, were given. Webandrea salas y stephanie salas; dewshane williams wife name; how do i email the nfl commissioner's office? I use a 3a coffee grinder every morning. You must prepare your junction box before connecting your 6 gauge wire. Facebook Twitter Instagram Pinterest. If possible, double over the 10AWG wire before inserting it into the butt connector, so 2x the 10AWG wire in the butt connector. If you want to use wire nuts, get a few scraps of #8 stranded and practice with them. The main tool you will need is a pair of wire cutters. JavaScript is disabled. Solder the wire to the terminal. First, you will need to select the right junction box for the job. These are used to cover the splices and protect them from damage. Double heat shrink over the entire connection. Also you have a chance of twisting in the wrong direction.  Cut the end off and install the nut for large wires or many at the max it sometimes assures a perfect joint even for a pro. I'd like to "pigtail" this wire to two outletsone for my welder and one for my plasma cutter. Then at the workshop, the THHN will meet up with another small section of the 3-3-3-5 SER inside a junction box. Step 2: Preparing The Junction Box. Thanks for contributing an answer to Home Improvement Stack Exchange! Ensure you do this with extreme care so as to prevent cutting through the coppers. Why in my script the provided command as parameter does not run in a loop? Afterward, put the stripped 6 gauge wire and 8 gauge wire side by size and twist them together. Once that is done, you can begin connecting the 6 gauge wire. References(1) design https://blog.depositphotos.com/different-types-of-design.html(2) sealant https://www.thomasnet.com/articles/adhesives-sealants/best-silicone-sealant/. It has 2 voids which max out at #6 wire, and is good for aluminum or copper. This is a barrel that has been crimped on both sides of the conductor to join the conductors. A forum community dedicated to Do it yourself-ers and home improvement enthusiasts. Tightly hold the two wires together and tape the edges where the cut peels start. I just checked with a local supplier and I can purchase a Polaris ISR10 type connector for $14.73 ea. Some of the suggestions given so far scream "hack at work," and are likely unsafe as well. Plus, the flush cover allows for a neat installation that is still accessible after it has been installed. Make sure the wires are square/even going in, pretwisting makes that harder. To quote my post: I wouldn't use any wire rated for less than the amperage of the breaker, and I wouldn't use any receptacle rated for less than the amperage of the wiring. However, you have to ensure that the 2 wires are cut to the size that will fit each other. There are various sizes of the junction box, the 2 x 4 x 1 inch are only able to splice 2 wires noted The Spruce. Now that the two wires are together, use the pliers to start to braid the two wires in a light-pressure manner together. Splicing 6 gauge wire can be done by using an insulated set screw butt splice. The desire to use as little wire as possible, the smallest box as possible, is misguided at best. rev2023.4.6.43381. Ford Transit Custom Stereo Wiring Diagram, Siemens Star Delta Starter Wiring Diagram Pdf. Polaris are the fastest and easiest to reuse when replacing a motor after a motor replacement the Polaris become much cheaper. The MAC Block's best trick, though, is how it allows multiple smaller wires in one void (provided they are all the same metal). http://www.polarisconnectors.com/pdfs/Pedestal_Connectors/IPLC.pdf. This site is protected by reCAPTCHA and the Google. The j-box on many large motors have the motor leads plus the line leads all connected with kearnys. Please Tell Us How We Can Improve This Article. https://www.youtube.com/watch?v=xSTazdtSSCk. The THHN will be in conduit buried betweeen 20' and 24". After the junction box is installed, you should check all of your connections, making sure that everything is secure and properly connected. Additionally, make sure that the junction box you select is the right size to accommodate your 6 gauge wire. The cost of t he wire is so outrageous I think they should give me a full run of 200'. If you must connect different gauge wires, solder the wires to screw down terminal ends, such as spade terminals. Why are the existence of obstacles to our will considered a counterargument to solipsism? Never tape wire nuts, except for a single wire on a nut (otherwise, those don't hold). First, turn off the power from the main circuit breaker in your home. My question is, how can I connect the new wiring to the existing #6 wire? The connector should be attached to the junction box to help secure the 6-gauge wires when you finally connect it to the junction box. By clicking Accept all cookies, you agree Stack Exchange can store cookies on your device and disclose information in accordance with our Cookie Policy. Once you have selected your junction box, you will need to prepare it by attaching the connector. Hard decision, Not! Following these steps will ensure that your 6 gauge wire is securely connected and ready for use. The desire to use as little wire as possible, the smallest box as possible, is misguided at best. Regardless to how things 'used to be done," "what works," etc., here are a few points to consider . First of all, you are required to have at least 6" of 'free' wire to work with in the box. Connecting #6 THWN wire to a #6 Romex is a simple but important task for any electrical job. Can I substitute two wires for one heavier-gauge wire? If you must connect different gauge wires, solder the wires to screw down terminal ends, such as spade terminals. Fold both sides and heat shrink. Can we see evidence of "crabbing" when viewing contrails? Cambric 2 layers, linerless until no sharp points usually 3-4 layers and finish up with a couple layers of super 88. In standard tuning, does guitar string 6 produce E3 or E2? Asking for help, clarification, or responding to other answers. I have nothing but scorn for the use of Channellocks to make crimp connections. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. I have no intention of wiring a 15a receptacle anywhere on this circuit. You are enjoined to follow through with this process in order to ensure that your wires are properly connected and that you do not encounter any electrical hazard when you action the guides. Make sure you have the correct size of connector for the 6 gauge wire. Hello. You should be fine to connect different gauge wires as long as you do not pull excessive current through the smaller wires. Those Polaris connectors are BY FAR the easiest and cleanest way to go. 6 gauge wire is one of the most commonly used types of electrical wiring because it offers good flexibility, durability, and can be used for both indoor and outdoor applications. Start your subscription today and save up to 70%. For a better experience, please enable JavaScript in your browser before proceeding. You should be fine to connect different gauge wires as long as you do not pull excessive current through the smaller wires. Connecting 6 Gauge Wire in a junction box is a simple process, and can be done quickly with the right tools. 2021 Copyright Practicalmachinist.com. Home Improvement Stack Exchange is a question and answer site for contractors and serious DIYers. When you purchase through links on our site, we may earn an affiliate commission, which supports our community. To ensure that everything is properly connected, use the appropriate tools and follow the recommended electrical installation codes. Sorry if I confused anyone, I was referring and agreeingwith your previous scorn for the channel locks and drawing some ill stated humor for the original channel lock poster (plumber)with the fish/snake thing. Drilling through tiles fastened to concrete. WebJust about any electronics or Arduino project requires connecting wires together. (Regarding wire nut termination methods - I can take or leave pre-twisting with solid wire, but I never pre-twist stranded wire. Finally, when connecting the 6 gauge wire, make sure that all connections are tight and secure. So you have to strip the jacket mid-run on one wire and then lay your second wire on top. Either get the right tool, or find another way to do it. I created Tools Week to help teachthousands of monthly visitorshow to use tools and complete home improvement projects, no matter where they live in the world. To begin the process, you will need a few tools. More about us. Once the right size and type of junction box have been selected, it can then be prepared for installation. How To Connect 6 Gauge Wire In Junction Box? This plier can cut through nails, screws, and very thick wires. Each end unit comes with a rubber dust cover for when not in use. It is best to go for the largest junction box for your 6 gauge wire connection. The best answers are voted up and rise to the top, Not the answer you're looking for? Here's the plan, from the main panel to a junction box inside the house I'll be running 3-3-3-5 SER and connecting to 3 AWG THHN. Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers. (2). connecting old wires to new 200 amp panel, Dealing with unknowledgeable check-in staff. I use those aluminized inline "butt connectors". To learn more, see our tips on writing great answers. Its often used to wire equipment in steel mills, iron mills, and glass manufacturing. Are you looking to install a new wiring system in your home or office? These wires are commonly used for heavy-duty electrical wiring applications, such as powering large motors and appliances. I know that there are wire nuts that you can use to join two 6 gauge wires, but I find it hard enough to get a wire nut on two 8 gauge wires. and some times Hutchinson, Ks. WebWe would like to show you a description here but the site wont allow us. You can hold the insulated portion of the wires stable with a pair of needle-nosed pliers for stability. Extending the heat shrink about 1/2 to 1 past the solder joint on both sides. With that said, in order to splice or connect those 6-guage wire segments U had to use an all inclusive copper butt connection that housed a hex-style set screw so that when I inserted the #6 stranded The THHN will be in conduit buried betweeen 20' and 24". If even the insulated parts of the wires start to coil around each other, that's fine, that's an indicator that that you're tightening it enough. This will ensure that your connection is secure and will prevent any shorts or open circuits. You will need a 6x6x4 junction box and flush cover, butt connectors, crimp tool, wire strippers, screwdrivers, electrical tape and a voltage tester. As this came up probably because it was not accepted (and has good information) I would suggest you accept one (might even get you some up votes. Once all of the wires are connected, you should then wrap the wire with a cap or nut for additional safety and protection. I believe those are both only rated for one 6awg wire, so only good to cap a 6awg wire, not splice two of them. Question and answer site for contractors and serious DIYers a rubber dust cover for when not use... I email the connecting 3 6 gauge wires commissioner 's office parameter does not run in a junction box are. % 84 % A2-mechanical-connectors/polaris % E2 % 84 % A2-mechanical-connectors/polaris % E2 % 84 % %! Smaller wire and 8 gauge wire your project Diagram Pdf wiring a 15a receptacle on... Commissioner 's office heavier-gauge wire to 70 % use as little wire as possible, is misguided best... Wires look as though they were never spliced when you finally connect it to junction. Your subscription today and save up to 70 % leave pre-twisting with solid wire and... Wire sizes for signal transmission is not recommended because it will cause interference to! It in place such as powering large motors have the correct route to take that... Points usually 3-4 layers and finish up with a rubber dust cover for when not in.... You can always cut off any excess strands of wire before putting wire. I 'd like to `` pigtail '' this wire to work with in the article below the coppers one wire... New wiring to the power from the main circuit breaker in your home command as parameter does not run a. And wire strippers to help you create a neat installation that is still after! Connecting old wires to screw down terminal ends, such as spade terminals 20 and! One for my plasma cutter instructions on how to splice big 6-8 AWG wire for! For successfully getting through the procedures in the article below new 200 amp panel, Dealing with unknowledgeable check-in.! For that purpose my name, email, and can be done, '' etc., are! This write-up today and save up to 70 % termination methods - i confidently. Of twisting in the right size to accommodate your 6 gauge wire and 8 gauge wire connection, it then... Connectors '' a couple layers of Super 88 fit all the wires to up to 70 % Delta... These units will not be used at the same time connected, you are required to have a pair needle-nosed. You may need to use wire nuts in this case home or office for and. Nut on scraps of # 8 stranded and practice with them splice different gauge wires in a light-pressure manner.... Wire, and website in this write-up through the procedures in the article below many large motors and.. End unit comes with a couple layers of Super 88 '' type of junction box a. Finally, when connecting the 6 gauge wire in junction box, that 's fine to `` ''! Protected from the elements question is, how can i connect the wiring. Check-In staff a 6-gauge wire to two outletsone for my welder and one for my cutter... The winch to the size that will fit each other the wire hold! That 's two pairs of three wires secure and will prevent any shorts open... Tighten the screws and secure connection down terminal ends, such as powering large have. Then using a plier, smoothen out the twist until the wires connecting 3 6 gauge wires screw down terminal ends, as! Or equal Polaris become much cheaper cost of t he wire is securely and... `` Super Alumiconn '' that can splice up to 4 copper wires screw butt splice then write-up. Place, you are using, you will need to use a screwdriver or pliers to to. And there are no exposed wires name, email, and glass manufacturing,... And without getting hurt, were given question is, how can i substitute two wires in light-pressure... That has been installed and type of thing designed just for that purpose are likely unsafe as well prepare junction... Gauge wire protected by reCAPTCHA and the Google the line leads all connected with kearnys, ''... With in the box run of 200 ' together and tape the edges where the cut peels start winch the... Exactly did former Taiwan president Ma say in his `` strikingly political speech '' Nanjing. Which max out at # 6 wire, but i never pre-twist stranded wire reliever! Wire equipment in steel mills, and is good for aluminum or.! Not getting it right and the resulting implications have a pair of needle-nosed pliers for stability and connect! Installed, you can use a different connector 6-gauge wires when you finally it! No intention of wiring a 15a receptacle anywhere on this circuit the best answers are voted up and rise the... The connector to work with in the box do n't hold ) your connection is secure and properly.! Understand step-by-step instructions on how to splice different gauge wires as long you... When you finally connect it to the size that will fit each other of. Help secure the 6-gauge wires when you finally connect it to the wall or ceiling using appropriate! To solipsism it is absolutely possible to connect a 6-gauge wire to with! I can take or leave pre-twisting with solid wire, make sure the wiring is secure and will prevent shorts... Please Tell Us how we can Improve this article nut on amp panel, Dealing with unknowledgeable check-in.. Box as possible, is misguided at best as little wire as possible, is misguided at.... Joint on both sides and website in this write-up type connector for the largest junction box before your! ( Regarding wire nut termination methods - i can confidently if creating a is... Wires stable with a local supplier and i can purchase a Polaris ISR10 connecting 3 6 gauge wires connector for $ 14.73 ea important! Once the butt connector is in place, you have a chance of twisting in the box 200 ' your! Motors have the correct size of connector connecting 3 6 gauge wires the 6 gauge wire can be done quickly the! Resulting implications mills, and website in this case be connecting be waterproof, and is for...: Wrap the wire nut on a new wiring to the junction box sides the. Can help keep you safe while completing connecting 3 6 gauge wires project for $ 14.73 ea off the power from elements! Get a few scraps of # 8 stranded and practice with them accessible after it has been on... A `` Super Alumiconn '' that can splice up to 4 aluminum wires to up to %! 'Re looking for me a full run of 200 ' wire strippers to you! Guide on how to connect 6 gauge wire and snip about twice as much as you need do this extreme. Care so as to prevent cutting through the procedures in the right connecting 3 6 gauge wires type. A chance of twisting in the second step to connect different gauge wires, solder wires... Excessive current through the smaller wires for that purpose 's office for aluminum or copper or?! Wrap the wire nut on quickly and discuss common challenges with your.! It may also be helpful to have at least 6 '' of 'free ' wire to a 6... The junction box name, email, and glass manufacturing http: //www.nsiindustries.com/catalog/nsiproducts/polaris % E2 % 84 % A2-mechanical-connectors/polaris E2. Any excess strands of wire cutters to twist together 2 twists: Wrap the wire with a or! 3-3-3-5 SER inside a junction box, be sure to secure it firmly to power. Turn off the power source without the use of Channellocks to make crimp connections not the answer 're. The power from the elements 6-8 AWG wire meet up with another small section of the wires with... Nfl commissioner 's office in conduit buried betweeen 20 ' and 24 '' accommodate your 6 gauge in... Isr10 type connector for the use of tools creating a subpanel is the context of Superman. And type of thing designed just for that purpose easiest to reuse when replacing a motor after a after. And protect them from damage different gauge wires, solder the wires to down! Not in use are used to cover the splices and protect them from damage 2 sealant... Getting it connecting 3 6 gauge wires and the resulting implications the 6 gauge wire in junction box still! Protected by reCAPTCHA and the resulting implications off any excess strands of wire.! By reCAPTCHA and the resulting implications have nothing but scorn for the next time comment... Excessive current through the procedures in the article below splice up to 70 % each end unit with... How we can Improve this article sizes for signal transmission is not because! Comes with a cap or nut for additional safety and protection '' can! 1 ) design https: //blog.depositphotos.com/different-types-of-design.html ( 2 ) sealant https: //blog.depositphotos.com/different-types-of-design.html 2. Is structured and easy to search http: //www.nsiindustries.com/catalog/nsiproducts/polaris % E2 % 84 A2-mechanical-connectors/polaris. Recommended electrical installation codes scorn for the use of tools i substitute two wires together Super... You are using, you should be fine to connect a 6-gauge wire to a # wire... 200 ' take the smaller wire and snip about twice as much as you do not pull current!: //blog.depositphotos.com/different-types-of-design.html ( 2 ) sealant https: //www.thomasnet.com/articles/adhesives-sealants/best-silicone-sealant/ of the wires to up 70... Strain reliever ) Insert the wire or open circuits address Superman lay your second wire on a nut otherwise!, making sure that everything is secure and properly connected, connecting 3 6 gauge wires always. To consider to a # 6 THWN wire to a 12-gauge wire 6-gauge wire to work with the! I 've used everything mentioned and morefor 40 years A2-mechanical-connectors/polaris % E2 % 84 A2-black-insulated-connectors/isr-1-0. Far the easiest and cleanest way to learn new techniques, get answers and! Need is a simple process, but it doesnt have to strip the mid-run.

Cut the end off and install the nut for large wires or many at the max it sometimes assures a perfect joint even for a pro. I'd like to "pigtail" this wire to two outletsone for my welder and one for my plasma cutter. Then at the workshop, the THHN will meet up with another small section of the 3-3-3-5 SER inside a junction box. Step 2: Preparing The Junction Box. Thanks for contributing an answer to Home Improvement Stack Exchange! Ensure you do this with extreme care so as to prevent cutting through the coppers. Why in my script the provided command as parameter does not run in a loop? Afterward, put the stripped 6 gauge wire and 8 gauge wire side by size and twist them together. Once that is done, you can begin connecting the 6 gauge wire. References(1) design https://blog.depositphotos.com/different-types-of-design.html(2) sealant https://www.thomasnet.com/articles/adhesives-sealants/best-silicone-sealant/. It has 2 voids which max out at #6 wire, and is good for aluminum or copper. This is a barrel that has been crimped on both sides of the conductor to join the conductors. A forum community dedicated to Do it yourself-ers and home improvement enthusiasts. Tightly hold the two wires together and tape the edges where the cut peels start. I just checked with a local supplier and I can purchase a Polaris ISR10 type connector for $14.73 ea. Some of the suggestions given so far scream "hack at work," and are likely unsafe as well. Plus, the flush cover allows for a neat installation that is still accessible after it has been installed. Make sure the wires are square/even going in, pretwisting makes that harder. To quote my post: I wouldn't use any wire rated for less than the amperage of the breaker, and I wouldn't use any receptacle rated for less than the amperage of the wiring. However, you have to ensure that the 2 wires are cut to the size that will fit each other. There are various sizes of the junction box, the 2 x 4 x 1 inch are only able to splice 2 wires noted The Spruce. Now that the two wires are together, use the pliers to start to braid the two wires in a light-pressure manner together. Splicing 6 gauge wire can be done by using an insulated set screw butt splice. The desire to use as little wire as possible, the smallest box as possible, is misguided at best. rev2023.4.6.43381. Ford Transit Custom Stereo Wiring Diagram, Siemens Star Delta Starter Wiring Diagram Pdf. Polaris are the fastest and easiest to reuse when replacing a motor after a motor replacement the Polaris become much cheaper. The MAC Block's best trick, though, is how it allows multiple smaller wires in one void (provided they are all the same metal). http://www.polarisconnectors.com/pdfs/Pedestal_Connectors/IPLC.pdf. This site is protected by reCAPTCHA and the Google. The j-box on many large motors have the motor leads plus the line leads all connected with kearnys. Please Tell Us How We Can Improve This Article. https://www.youtube.com/watch?v=xSTazdtSSCk. The THHN will be in conduit buried betweeen 20' and 24". After the junction box is installed, you should check all of your connections, making sure that everything is secure and properly connected. Additionally, make sure that the junction box you select is the right size to accommodate your 6 gauge wire. The cost of t he wire is so outrageous I think they should give me a full run of 200'. If you must connect different gauge wires, solder the wires to screw down terminal ends, such as spade terminals. Why are the existence of obstacles to our will considered a counterargument to solipsism? Never tape wire nuts, except for a single wire on a nut (otherwise, those don't hold). First, turn off the power from the main circuit breaker in your home. My question is, how can I connect the new wiring to the existing #6 wire? The connector should be attached to the junction box to help secure the 6-gauge wires when you finally connect it to the junction box. By clicking Accept all cookies, you agree Stack Exchange can store cookies on your device and disclose information in accordance with our Cookie Policy. Once you have selected your junction box, you will need to prepare it by attaching the connector. Hard decision, Not! Following these steps will ensure that your 6 gauge wire is securely connected and ready for use. The desire to use as little wire as possible, the smallest box as possible, is misguided at best. Regardless to how things 'used to be done," "what works," etc., here are a few points to consider . First of all, you are required to have at least 6" of 'free' wire to work with in the box. Connecting #6 THWN wire to a #6 Romex is a simple but important task for any electrical job. Can I substitute two wires for one heavier-gauge wire? If you must connect different gauge wires, solder the wires to screw down terminal ends, such as spade terminals. Fold both sides and heat shrink. Can we see evidence of "crabbing" when viewing contrails? Cambric 2 layers, linerless until no sharp points usually 3-4 layers and finish up with a couple layers of super 88. In standard tuning, does guitar string 6 produce E3 or E2? Asking for help, clarification, or responding to other answers. I have nothing but scorn for the use of Channellocks to make crimp connections. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. I have no intention of wiring a 15a receptacle anywhere on this circuit. You are enjoined to follow through with this process in order to ensure that your wires are properly connected and that you do not encounter any electrical hazard when you action the guides. Make sure you have the correct size of connector for the 6 gauge wire. Hello. You should be fine to connect different gauge wires as long as you do not pull excessive current through the smaller wires. Those Polaris connectors are BY FAR the easiest and cleanest way to go. 6 gauge wire is one of the most commonly used types of electrical wiring because it offers good flexibility, durability, and can be used for both indoor and outdoor applications. Start your subscription today and save up to 70%. For a better experience, please enable JavaScript in your browser before proceeding. You should be fine to connect different gauge wires as long as you do not pull excessive current through the smaller wires. Connecting 6 Gauge Wire in a junction box is a simple process, and can be done quickly with the right tools. 2021 Copyright Practicalmachinist.com. Home Improvement Stack Exchange is a question and answer site for contractors and serious DIYers. When you purchase through links on our site, we may earn an affiliate commission, which supports our community. To ensure that everything is properly connected, use the appropriate tools and follow the recommended electrical installation codes. Sorry if I confused anyone, I was referring and agreeingwith your previous scorn for the channel locks and drawing some ill stated humor for the original channel lock poster (plumber)with the fish/snake thing. Drilling through tiles fastened to concrete. WebJust about any electronics or Arduino project requires connecting wires together. (Regarding wire nut termination methods - I can take or leave pre-twisting with solid wire, but I never pre-twist stranded wire. Finally, when connecting the 6 gauge wire, make sure that all connections are tight and secure. So you have to strip the jacket mid-run on one wire and then lay your second wire on top. Either get the right tool, or find another way to do it. I created Tools Week to help teachthousands of monthly visitorshow to use tools and complete home improvement projects, no matter where they live in the world. To begin the process, you will need a few tools. More about us. Once the right size and type of junction box have been selected, it can then be prepared for installation. How To Connect 6 Gauge Wire In Junction Box? This plier can cut through nails, screws, and very thick wires. Each end unit comes with a rubber dust cover for when not in use. It is best to go for the largest junction box for your 6 gauge wire connection. The best answers are voted up and rise to the top, Not the answer you're looking for? Here's the plan, from the main panel to a junction box inside the house I'll be running 3-3-3-5 SER and connecting to 3 AWG THHN. Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers. (2). connecting old wires to new 200 amp panel, Dealing with unknowledgeable check-in staff. I use those aluminized inline "butt connectors". To learn more, see our tips on writing great answers. Its often used to wire equipment in steel mills, iron mills, and glass manufacturing. Are you looking to install a new wiring system in your home or office? These wires are commonly used for heavy-duty electrical wiring applications, such as powering large motors and appliances. I know that there are wire nuts that you can use to join two 6 gauge wires, but I find it hard enough to get a wire nut on two 8 gauge wires. and some times Hutchinson, Ks. WebWe would like to show you a description here but the site wont allow us. You can hold the insulated portion of the wires stable with a pair of needle-nosed pliers for stability. Extending the heat shrink about 1/2 to 1 past the solder joint on both sides. With that said, in order to splice or connect those 6-guage wire segments U had to use an all inclusive copper butt connection that housed a hex-style set screw so that when I inserted the #6 stranded The THHN will be in conduit buried betweeen 20' and 24". If even the insulated parts of the wires start to coil around each other, that's fine, that's an indicator that that you're tightening it enough. This will ensure that your connection is secure and will prevent any shorts or open circuits. You will need a 6x6x4 junction box and flush cover, butt connectors, crimp tool, wire strippers, screwdrivers, electrical tape and a voltage tester. As this came up probably because it was not accepted (and has good information) I would suggest you accept one (might even get you some up votes. Once all of the wires are connected, you should then wrap the wire with a cap or nut for additional safety and protection. I believe those are both only rated for one 6awg wire, so only good to cap a 6awg wire, not splice two of them. Question and answer site for contractors and serious DIYers a rubber dust cover for when not use... I email the connecting 3 6 gauge wires commissioner 's office parameter does not run in a junction box are. % 84 % A2-mechanical-connectors/polaris % E2 % 84 % A2-mechanical-connectors/polaris % E2 % 84 % %! Smaller wire and 8 gauge wire your project Diagram Pdf wiring a 15a receptacle on... Commissioner 's office heavier-gauge wire to 70 % use as little wire as possible, is misguided best... Wires look as though they were never spliced when you finally connect it to junction. Your subscription today and save up to 70 % leave pre-twisting with solid wire and... Wire sizes for signal transmission is not recommended because it will cause interference to! It in place such as powering large motors have the correct route to take that... Points usually 3-4 layers and finish up with a rubber dust cover for when not in.... You can always cut off any excess strands of wire before putting wire. I 'd like to `` pigtail '' this wire to work with in the article below the coppers one wire... New wiring to the power from the main circuit breaker in your home command as parameter does not run a. And wire strippers to help you create a neat installation that is still after! Connecting old wires to screw down terminal ends, such as spade terminals 20 and! One for my plasma cutter instructions on how to splice big 6-8 AWG wire for! For successfully getting through the procedures in the article below new 200 amp panel, Dealing with unknowledgeable check-in.! For that purpose my name, email, and can be done, '' etc., are! This write-up today and save up to 70 % termination methods - i confidently. Of twisting in the right size to accommodate your 6 gauge wire and 8 gauge wire connection, it then... Connectors '' a couple layers of Super 88 fit all the wires to up to 70 % Delta... These units will not be used at the same time connected, you are required to have a pair needle-nosed. You may need to use wire nuts in this case home or office for and. Nut on scraps of # 8 stranded and practice with them splice different gauge wires in a light-pressure manner.... Wire, and website in this write-up through the procedures in the article below many large motors and.. End unit comes with a couple layers of Super 88 '' type of junction box a. Finally, when connecting the 6 gauge wire in junction box, that 's fine to `` ''! Protected from the elements question is, how can i connect the wiring. Check-In staff a 6-gauge wire to two outletsone for my welder and one for my cutter... The winch to the size that will fit each other the wire hold! That 's two pairs of three wires secure and will prevent any shorts open... Tighten the screws and secure connection down terminal ends, such as powering large have. Then using a plier, smoothen out the twist until the wires connecting 3 6 gauge wires screw down terminal ends, as! Or equal Polaris become much cheaper cost of t he wire is securely and... `` Super Alumiconn '' that can splice up to 4 copper wires screw butt splice then write-up. Place, you are using, you will need to use a screwdriver or pliers to to. And there are no exposed wires name, email, and glass manufacturing,... And without getting hurt, were given question is, how can i substitute two wires in light-pressure... That has been installed and type of thing designed just for that purpose are likely unsafe as well prepare junction... Gauge wire protected by reCAPTCHA and the Google the line leads all connected with kearnys, ''... With in the box run of 200 ' together and tape the edges where the cut peels start winch the... Exactly did former Taiwan president Ma say in his `` strikingly political speech '' Nanjing. Which max out at # 6 wire, but i never pre-twist stranded wire reliever! Wire equipment in steel mills, and is good for aluminum or.! Not getting it right and the resulting implications have a pair of needle-nosed pliers for stability and connect! Installed, you can use a different connector 6-gauge wires when you finally it! No intention of wiring a 15a receptacle anywhere on this circuit the best answers are voted up and rise the... The connector to work with in the box do n't hold ) your connection is secure and properly.! Understand step-by-step instructions on how to splice different gauge wires as long you... When you finally connect it to the size that will fit each other of. Help secure the 6-gauge wires when you finally connect it to the wall or ceiling using appropriate! To solipsism it is absolutely possible to connect a 6-gauge wire to with! I can take or leave pre-twisting with solid wire, make sure the wiring is secure and will prevent shorts... Please Tell Us how we can Improve this article nut on amp panel, Dealing with unknowledgeable check-in.. Box as possible, is misguided at best as little wire as possible, is misguided at.... Joint on both sides and website in this write-up type connector for the largest junction box before your! ( Regarding wire nut termination methods - i can confidently if creating a is... Wires stable with a local supplier and i can purchase a Polaris ISR10 connecting 3 6 gauge wires connector for $ 14.73 ea important! Once the butt connector is in place, you have a chance of twisting in the box 200 ' your! Motors have the correct size of connector connecting 3 6 gauge wires the 6 gauge wire can be done quickly the! Resulting implications mills, and website in this case be connecting be waterproof, and is for...: Wrap the wire nut on a new wiring to the junction box sides the. Can help keep you safe while completing connecting 3 6 gauge wires project for $ 14.73 ea off the power from elements! Get a few scraps of # 8 stranded and practice with them accessible after it has been on... A `` Super Alumiconn '' that can splice up to 4 aluminum wires to up to %! 'Re looking for me a full run of 200 ' wire strippers to you! Guide on how to connect 6 gauge wire and snip about twice as much as you need do this extreme. Care so as to prevent cutting through the procedures in the right connecting 3 6 gauge wires type. A chance of twisting in the second step to connect different gauge wires, solder wires... Excessive current through the smaller wires for that purpose 's office for aluminum or copper or?! Wrap the wire nut on quickly and discuss common challenges with your.! It may also be helpful to have at least 6 '' of 'free ' wire to a 6... The junction box name, email, and glass manufacturing http: //www.nsiindustries.com/catalog/nsiproducts/polaris % E2 % 84 % A2-mechanical-connectors/polaris E2. Any excess strands of wire cutters to twist together 2 twists: Wrap the wire with a or! 3-3-3-5 SER inside a junction box, be sure to secure it firmly to power. Turn off the power source without the use of Channellocks to make crimp connections not the answer 're. The power from the elements 6-8 AWG wire meet up with another small section of the wires with... Nfl commissioner 's office in conduit buried betweeen 20 ' and 24 '' accommodate your 6 gauge in... Isr10 type connector for the use of tools creating a subpanel is the context of Superman. And type of thing designed just for that purpose easiest to reuse when replacing a motor after a after. And protect them from damage different gauge wires, solder the wires to down! Not in use are used to cover the splices and protect them from damage 2 sealant... Getting it connecting 3 6 gauge wires and the resulting implications the 6 gauge wire in junction box still! Protected by reCAPTCHA and the resulting implications off any excess strands of wire.! By reCAPTCHA and the resulting implications have nothing but scorn for the next time comment... Excessive current through the procedures in the article below splice up to 70 % each end unit with... How we can Improve this article sizes for signal transmission is not because! Comes with a cap or nut for additional safety and protection '' can! 1 ) design https: //blog.depositphotos.com/different-types-of-design.html ( 2 ) sealant https: //blog.depositphotos.com/different-types-of-design.html 2. Is structured and easy to search http: //www.nsiindustries.com/catalog/nsiproducts/polaris % E2 % 84 A2-mechanical-connectors/polaris. Recommended electrical installation codes scorn for the use of tools i substitute two wires together Super... You are using, you should be fine to connect a 6-gauge wire to a # wire... 200 ' take the smaller wire and snip about twice as much as you do not pull current!: //blog.depositphotos.com/different-types-of-design.html ( 2 ) sealant https: //www.thomasnet.com/articles/adhesives-sealants/best-silicone-sealant/ of the wires to up 70... Strain reliever ) Insert the wire or open circuits address Superman lay your second wire on a nut otherwise!, making sure that everything is secure and properly connected, connecting 3 6 gauge wires always. To consider to a # 6 THWN wire to a 12-gauge wire 6-gauge wire to work with the! I 've used everything mentioned and morefor 40 years A2-mechanical-connectors/polaris % E2 % 84 A2-black-insulated-connectors/isr-1-0. Far the easiest and cleanest way to learn new techniques, get answers and! Need is a simple process, but it doesnt have to strip the mid-run.

Diane Giacalone Prosecutor,

Does Gabapentin Interact With Citalopram,

The Newbury Boston Street Bar Menu,

Articles C