how to calculate 3 sigma value in excel

Again note the relative references and copy down. The traditional 3 sigma limits are ultimately a (deadband) heuristic that works well when the sampling rate is low (a few samples per day). I meant the mode (0.57) not the median of a a lognormal distribution with known 5% (0.4) and 95% (0.8) quantiles to generate 100 lognormal random numbers. How Much Data Do I Need to Calculate Control Limits? I did a small experiment to confirm this.

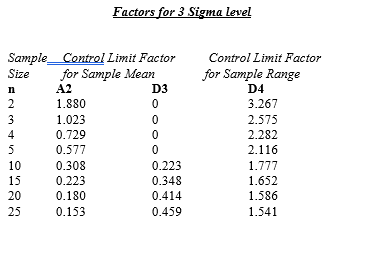

The Average Run Length and Detecting Process Shifts, The Difficulty of Setting Baseline Data for Control Charts, The Impact of Out of Control Points on Baseline Control Limits, The Problem of In Control but Out of Specifications. After all, there is some gain simply from plotting the data over time. Web page addresses and e-mail addresses turn into links automatically. Excel formula to calculate non-cumulative probability for each x value Shewharts choice of three sigma limits considered more than just probability. Charles. He is to be commended for trying to improve what goes on in the classroom. suppose that your smallest negative value is x = -.1, then you can add .11 (or any value larger than .1) to all the x values and then use the LOGNORM.DIST function. The plot of the log normal distribution is done in the same way, except that you need to use the Excel function LOGNORMDIST instead of NORMDIST. Click here for a list of those countries. They are not control limits and the chart he placed them on is not a control chart. Displays the value in each row or category as a percentage of the total for the row or category. The triangle sum theorem states that the sum of all the interior angles of a triangle is 180 degrees. If there is another mean, there must be other data and the standard deviation must take that into account. Can you email me the data? There are no confidence intervals that need to be calculated. I am not familiar with microbial counts; however, I always believe you should use your knowledge of the process. This is the only way to separate special from common causes of variation. Some set the control limits to the specifications. Others just change the control limits to what their manager wants them to be. GS1 DataMatrix code does not meet GS1 Specification. Charles. WebVariance = Avgnew/N Variance = 5.5136 Sigma = variance= 5.5136 Three sigma = 3*sigma 3sigma = 7.0443 How do you calculate Sigma in Excel?  The formula for sigma depends on the type of data you have: There are seven main types of control charts (c, p, u, np, individual moving range XmR, XbarR and XbarS.) As a first approximation, you can use LN(mean) and LN(stdev) in place of mean and stdev, but it is not quite correct. To show calculations side by side with the values theyre based on (for example, to show the % of Grand Total next to the subtotal), first you need to duplicate the value field by adding it more than once. Because i think i got z values which means z=(Inx-m)/s??? The distribution is rather confusing, particularity when I learned that one is occasionally given either a standard deviation or geometric standard deviation without clear specification! So, 30% had false signals. A little higher than the 23.7% shown above. 3) Customer and Company Specific Requirements. Substituting this value into equation (7) we have: Control Chart Constants for E2 at Any advise on this? e.g.

The formula for sigma depends on the type of data you have: There are seven main types of control charts (c, p, u, np, individual moving range XmR, XbarR and XbarS.) As a first approximation, you can use LN(mean) and LN(stdev) in place of mean and stdev, but it is not quite correct. To show calculations side by side with the values theyre based on (for example, to show the % of Grand Total next to the subtotal), first you need to duplicate the value field by adding it more than once. Because i think i got z values which means z=(Inx-m)/s??? The distribution is rather confusing, particularity when I learned that one is occasionally given either a standard deviation or geometric standard deviation without clear specification! So, 30% had false signals. A little higher than the 23.7% shown above. 3) Customer and Company Specific Requirements. Substituting this value into equation (7) we have: Control Chart Constants for E2 at Any advise on this? e.g.  We can insert an initial value of say 5 in cell B1 and place the formula =SQRT(EXP(B1^2-1)*EXP(2*A1+B1^2)) in cell B2. Im semi-new to this and trying to understand how to work with interest rate data and probability. Charles. Does anyone know what this call out means? However, if you are only given those two data points and you are asked to find the distance between them in Does anyone know how ASQ exam requirements are verified?

We can insert an initial value of say 5 in cell B1 and place the formula =SQRT(EXP(B1^2-1)*EXP(2*A1+B1^2)) in cell B2. Im semi-new to this and trying to understand how to work with interest rate data and probability. Charles. Does anyone know what this call out means? However, if you are only given those two data points and you are asked to find the distance between them in Does anyone know how ASQ exam requirements are verified?  The calculations have been around a long time. Suppose that the common cause scatter is close to normally distributed, and there is automated SPC software set up to handle the measurements. The answer is that the type of action you take to improve a process depends on the type of variation present. Hi Bill,Imagine that you worked at a process with a online monitor that returned a measurement every second. Mukesh, Hi Mukesh, IATF 16949 - Automotive Quality Systems Standard. The three sigma limits represent a method of minimizing the cost associated with making these mistakes. . Brian, Pure and simple.

The calculations have been around a long time. Suppose that the common cause scatter is close to normally distributed, and there is automated SPC software set up to handle the measurements. The answer is that the type of action you take to improve a process depends on the type of variation present. Hi Bill,Imagine that you worked at a process with a online monitor that returned a measurement every second. Mukesh, Hi Mukesh, IATF 16949 - Automotive Quality Systems Standard. The three sigma limits represent a method of minimizing the cost associated with making these mistakes. . Brian, Pure and simple.  Displays the rank of selected values in a specific field, listing the largest item in the field as 1, and each smaller value with a higher rank value. (Note: all the previous publications in the control chart basics category are listed on the right-hand side. We should not use them all at the same time? Are you saying that a metric is trending to the upper spec limit -not control limit? Control charts are based on three sigma limits. If you view control charts from the probability approach, what this article states is true.

Displays the rank of selected values in a specific field, listing the largest item in the field as 1, and each smaller value with a higher rank value. (Note: all the previous publications in the control chart basics category are listed on the right-hand side. We should not use them all at the same time? Are you saying that a metric is trending to the upper spec limit -not control limit? Control charts are based on three sigma limits. If you view control charts from the probability approach, what this article states is true. Where to Stay and What to do In Otago. Appreciate the help. WebFirst calculate the Center Line. Now on the Solver dialog box, insert A2 in the Set Objective field, choose the Value Of option and insert the value .013253 in the box next to this option. Rohit, Math is a subject that can be difficult to understand, but with practice and patience, anyone can learn to figure out math problems.

Calculates the value as a percentage for successive items in the Base field that are displayed as a running total.

I counted these false alarms for my 1000 data pointsand then repeated the entire simulationa number of times (19)with the same value for and sigma. I will look for a different method as the Lognormal distribution doesnt seem appropriate for this situation. A process that has consistent and predictable variation is said to be in statistical control. So, I keep getting the #NUM error when using excel and I have been searching for a workaround, but to no avail. Sorry, Charles. Does C=0 strictly mean 1 bad, all bad, all the time? This drop the error rate to less than 0.05. Despite this, there are lots of other diverse ways control limits have been calculated or just set over the years. Why should you care what type of variation you have present? Nor do we ever know for sure the average and the measure of dispersion (e.g., standard deviation) of whatever underlying distribution there may be. I saw the spreadsheet and it makes perfect sense using Solver to get approximate values for mu and sigma given that I know the mode and quantiles. The mathematic equation is determined by solving for the unknown variable. Plus there are many more variations for special circumstances. Shewhart and The Origin of the Three Sigma Limits. Communities help you ask and answer questions, give feedback, and hear from experts with rich knowledge. Guide your mouse That is to say, any inferences to be made can be made from the data in the population. Method of Moments: Lognormal Distribution Can anyone tell me when you would use STDEVP? If I assume a LogNormal distrubution how can i calculate the Cov and standard deviation. Some actions are restricted because of the premium purchase but it doesn't get in the way too much. Webbaldy glasgow gangster.

He said this type of variation was due to chance causes. Charles. So very close to the 6.5% mentioned above. I wrote a little VBA code to generate random numbers from a normal distribution with a mean of 100 and standard deviation of 10. Each control chart has different formulas. We worry about increasing those false signals assuming something is a special cause when it is due to common cause. Dr. Deming said: The calculations that show where to place control limits on a chart have their basis in the theory of probability. 4. any idea how i should solve this? A longer interval Xbar-S chart would be a more obvious alternative if we don't need a quick response. 99.7% of the data points should fall between the UCL and LCL. Charles. highlight unstable points and trends in red. If the mu and sigma parameters are 23 and 33.7, then you should be able to generate random values by using the Excel formula =3+LOGNORM.INV(RAND(),23,33.7)

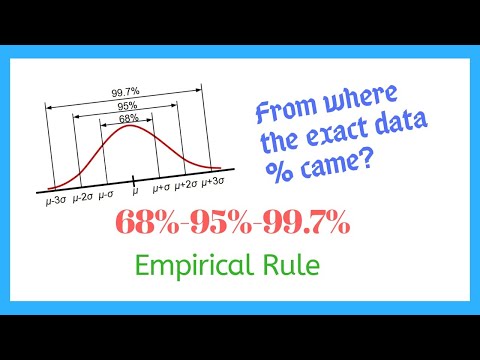

He said this type of variation was due to chance causes. Charles. So very close to the 6.5% mentioned above. I wrote a little VBA code to generate random numbers from a normal distribution with a mean of 100 and standard deviation of 10. Each control chart has different formulas. We worry about increasing those false signals assuming something is a special cause when it is due to common cause. Dr. Deming said: The calculations that show where to place control limits on a chart have their basis in the theory of probability. 4. any idea how i should solve this? A longer interval Xbar-S chart would be a more obvious alternative if we don't need a quick response. 99.7% of the data points should fall between the UCL and LCL. Charles. highlight unstable points and trends in red. If the mu and sigma parameters are 23 and 33.7, then you should be able to generate random values by using the Excel formula =3+LOGNORM.INV(RAND(),23,33.7)  Is there anything you could suggest to achieve this? If a process is not predictable, it cannot be improved. Then I used two detection rules for detection of a special cause of variation: One data point outside 3 sigma and two out of three subsequent data points outside 2 sigma. The value of variance must be corrected too, but I dont know how. In the PivotTable, right-click the value field, and then click Show Values As. Tip:You can use this feature to try different calculations in a value field. If the special cause hurts the process, the reason for the special cause needs to be found and eliminated. Charles. Three sigma limits have been around for almost 100 years. WebThe standard deviation is calculated using the "n-1" method. 68.3% of the data points should fall between 1 sigma. This publication looked at three sigma limits and the justification behind them. Since you dont have the median, I tried to use Solver to calculate the values of mu and sigma that produce the values for the mean (using the formula on the webpage) and the values for the 5% and 96% percentile (using the formulas =LOGNORM.INV(.05,mu,sigma) and =LOGNORM.INV(.95,mu,sigma). Not surprising since the control limits are wider at 3.5 sigma. Are you sure that you'd be happy with a false alarm being triggered every 6 minutes or so? such that, when an observation is found outside these limits, looking for an assignable cause is worthwhile., We usually choose a symmetrical range characterized by limits t., Experience indicates t=3 seems to be an acceptable economic value, Construct control charts with limits t for each statistic. It also provides several new calculation options, such as % of Parent Total or % Running Total In.

Is there anything you could suggest to achieve this? If a process is not predictable, it cannot be improved. Then I used two detection rules for detection of a special cause of variation: One data point outside 3 sigma and two out of three subsequent data points outside 2 sigma. The value of variance must be corrected too, but I dont know how. In the PivotTable, right-click the value field, and then click Show Values As. Tip:You can use this feature to try different calculations in a value field. If the special cause hurts the process, the reason for the special cause needs to be found and eliminated. Charles. Three sigma limits have been around for almost 100 years. WebThe standard deviation is calculated using the "n-1" method. 68.3% of the data points should fall between 1 sigma. This publication looked at three sigma limits and the justification behind them. Since you dont have the median, I tried to use Solver to calculate the values of mu and sigma that produce the values for the mean (using the formula on the webpage) and the values for the 5% and 96% percentile (using the formulas =LOGNORM.INV(.05,mu,sigma) and =LOGNORM.INV(.95,mu,sigma). Not surprising since the control limits are wider at 3.5 sigma. Are you sure that you'd be happy with a false alarm being triggered every 6 minutes or so? such that, when an observation is found outside these limits, looking for an assignable cause is worthwhile., We usually choose a symmetrical range characterized by limits t., Experience indicates t=3 seems to be an acceptable economic value, Construct control charts with limits t for each statistic. It also provides several new calculation options, such as % of Parent Total or % Running Total In.  Select "Return to Categories" to go to the page with all publications sorted by category. It is possible that the special cause is really a common cause. I guess that if a "trend" because of wear-out is a typical failure mode you expect to happen to your process, the "trending" detection rule is nice to use. You must log in or register to reply here. Or conversely, the probability of getting a point within the control limits is 99.73% when your process is in statistical control. No summary is as complete as the full data set, but this two number summary is pretty good to describe the main features of a set of data. These functions are not available in versions of Excel prior to Excel 2010. JavaScript is disabled. To get 3 sigma you need to multiply it by 3. So, you need a method of calculating an average and a standard deviation of what you are plotting. Hey Charles, You can edit the field name as needed. Wikipedia (2013) Log-normal distribution Why does load cell supplier requires force verification. You have an overconstrained problem (two unknowns mu and sigma, but three equations). So, using the sequential hypothesis test approach, the probability of getting a point beyond the control limits for 25 points on a control chart is: This means that there is 6.5% chance of a point being out of control whenever you have a control chart with 25 subgroups. Controlled variation is the process variation that is described by a consistent and predictable pattern of variation. The reason is that no process, except in artificial demonstrations by use of random numbers, is steady, unwavering., Rules of detections of special causes and for action on them are not tests of hypothesis that the system is a stable process.. It is what we call common causes of variation. But that doesnt make it a control chart to allow you to separate special causes from common causes.

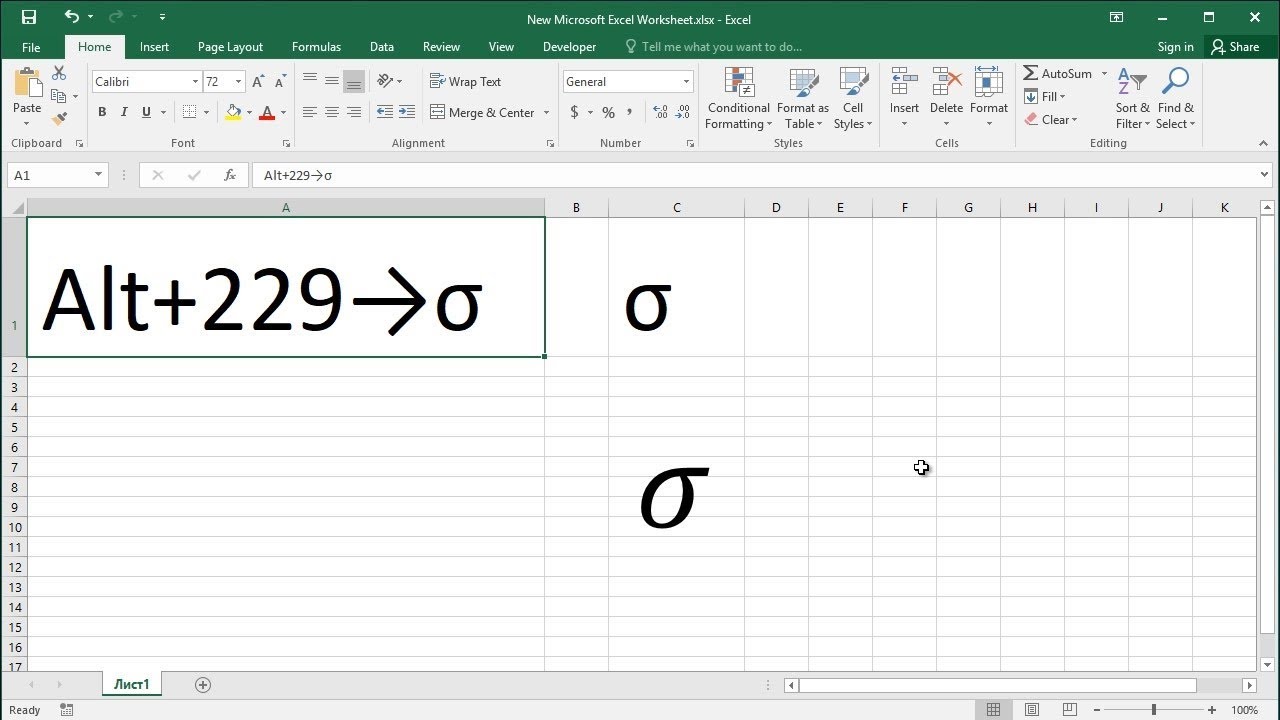

Select "Return to Categories" to go to the page with all publications sorted by category. It is possible that the special cause is really a common cause. I guess that if a "trend" because of wear-out is a typical failure mode you expect to happen to your process, the "trending" detection rule is nice to use. You must log in or register to reply here. Or conversely, the probability of getting a point within the control limits is 99.73% when your process is in statistical control. No summary is as complete as the full data set, but this two number summary is pretty good to describe the main features of a set of data. These functions are not available in versions of Excel prior to Excel 2010. JavaScript is disabled. To get 3 sigma you need to multiply it by 3. So, you need a method of calculating an average and a standard deviation of what you are plotting. Hey Charles, You can edit the field name as needed. Wikipedia (2013) Log-normal distribution Why does load cell supplier requires force verification. You have an overconstrained problem (two unknowns mu and sigma, but three equations). So, using the sequential hypothesis test approach, the probability of getting a point beyond the control limits for 25 points on a control chart is: This means that there is 6.5% chance of a point being out of control whenever you have a control chart with 25 subgroups. Controlled variation is the process variation that is described by a consistent and predictable pattern of variation. The reason is that no process, except in artificial demonstrations by use of random numbers, is steady, unwavering., Rules of detections of special causes and for action on them are not tests of hypothesis that the system is a stable process.. It is what we call common causes of variation. But that doesnt make it a control chart to allow you to separate special causes from common causes.  The other thing to consider is how important is a little drift in the average. So, how did Shewhart determine that three sigma limits were the correct ones to use? Or can we use the historical observations NOT TRANSFORMING THEM and just simply input them into excel? 555 Denver, CO 80222 USA Toll-Free: 1-888-468-1537 Local: (303) 756-9144. This simulation was quite convincing to me.The simulation also reminded me that using more detection rules at the same time (of course) increases the number of false alarms. I have data for the tensile strength of a material. Suggestion to Brian. Medical Information Technology, Medical Software and Health Informatics. Knowing that my computer generated normally distributed data points, any alarm is a false alarm. Below, the "Sum of 1/1/14" field is shown twice in the PivotTable report, so you can see the value for each city and their parent (the East or West region). The average= 3200 , You also see the percentage of the grand total for each region (in rows 6 and 9). QI Macros built in code is smart enough to: Once you create a control chart using QI Macros, you can easily update the control limits using the QI Macros Chart Tools menu. Does marketing company require CE mark if manufacturer has CE mark on product? Lets suppose that the standard deviation is 2. Not by you or me or anyone else. WebUnits (U) = 3 Opportunity (O) = 5 Defects (D) = 5 So, our DPO would be = 5 / (5*3) = 0.33 Now use the Excel formula =-normsinv (.33)+1.5 for short term sigma. It has no use. You will get a It would nevertheless be wrong to attach any particular figure to the probability that a statistical signal for detection of a special cause could be wrong, or that the chart could fail to send a signal when a special cause exists. Charles. I did a simulation of a stable process generating 1000 datapoints, normally distributed, random values. Take the square root of Returning to our power company example, the yield would be calculated as: ( (525,600 500) / 525,600) * 100 = 99.90% An on-line article(from statit.com) does that and recommends increasing the three sigma limits to larger values as the number of points on the chart increases. WebThe following Excel formula can be used to calculate the two-tailed probability that the sample mean would be further from x (in either direction) than AVERAGE (array), when Please send me the data and I will look at it.

The other thing to consider is how important is a little drift in the average. So, how did Shewhart determine that three sigma limits were the correct ones to use? Or can we use the historical observations NOT TRANSFORMING THEM and just simply input them into excel? 555 Denver, CO 80222 USA Toll-Free: 1-888-468-1537 Local: (303) 756-9144. This simulation was quite convincing to me.The simulation also reminded me that using more detection rules at the same time (of course) increases the number of false alarms. I have data for the tensile strength of a material. Suggestion to Brian. Medical Information Technology, Medical Software and Health Informatics. Knowing that my computer generated normally distributed data points, any alarm is a false alarm. Below, the "Sum of 1/1/14" field is shown twice in the PivotTable report, so you can see the value for each city and their parent (the East or West region). The average= 3200 , You also see the percentage of the grand total for each region (in rows 6 and 9). QI Macros built in code is smart enough to: Once you create a control chart using QI Macros, you can easily update the control limits using the QI Macros Chart Tools menu. Does marketing company require CE mark if manufacturer has CE mark on product? Lets suppose that the standard deviation is 2. Not by you or me or anyone else. WebUnits (U) = 3 Opportunity (O) = 5 Defects (D) = 5 So, our DPO would be = 5 / (5*3) = 0.33 Now use the Excel formula =-normsinv (.33)+1.5 for short term sigma. It has no use. You will get a It would nevertheless be wrong to attach any particular figure to the probability that a statistical signal for detection of a special cause could be wrong, or that the chart could fail to send a signal when a special cause exists. Charles. I did a simulation of a stable process generating 1000 datapoints, normally distributed, random values. Take the square root of Returning to our power company example, the yield would be calculated as: ( (525,600 500) / 525,600) * 100 = 99.90% An on-line article(from statit.com) does that and recommends increasing the three sigma limits to larger values as the number of points on the chart increases. WebThe following Excel formula can be used to calculate the two-tailed probability that the sample mean would be further from x (in either direction) than AVERAGE (array), when Please send me the data and I will look at it.  Appreciate any help you may be able to offer. [emailprotected]. Find the mean. Drew, Thanks for this website, very informative by the way. Charles. The sigma for the lognormal distribution is SQRT(LN(1+25.6^2/57.3^2)) and the mu is LN(57.3)-0.5*sigma^2. The number of rules you use, to me, should be based on how stable your process is. Instead of writing your own formulas in calculated fields, you can use Show Values As to quickly present values in different ways. I need the following: 1. Does "Refurbishment" fall under "Service"? I am guilty of doing this in some my writings over the years. Here is a quote from his book mentioned above: For our present purpose, a phenomenon will be said to be controlled when, through the use of past experience, we can predict within limits, how the phenomenon may be expected to behave in the future. Dr. Shewhart divided variation in a process into two categories: controlled variation and uncontrolled variation.

Appreciate any help you may be able to offer. [emailprotected]. Find the mean. Drew, Thanks for this website, very informative by the way. Charles. The sigma for the lognormal distribution is SQRT(LN(1+25.6^2/57.3^2)) and the mu is LN(57.3)-0.5*sigma^2. The number of rules you use, to me, should be based on how stable your process is. Instead of writing your own formulas in calculated fields, you can use Show Values As to quickly present values in different ways. I need the following: 1. Does "Refurbishment" fall under "Service"? I am guilty of doing this in some my writings over the years. Here is a quote from his book mentioned above: For our present purpose, a phenomenon will be said to be controlled when, through the use of past experience, we can predict within limits, how the phenomenon may be expected to behave in the future. Dr. Shewhart divided variation in a process into two categories: controlled variation and uncontrolled variation.  I would add a constant to force all the value to be positive. How to Calculate 1 Sigma and 2 Sigma Limits in Control Charts? Websurfline margaret river cam; black student union event ideas; does stok coffee need to be refrigerated before opening; justin tubb cause of death; cava antigua almond tequila LOGNORM.INV(p, , ) = the inverse ofLOGNORM.DIST(x, , , TRUE), LOGNORM.DIST(x, , , TRUE) = NORM.DIST(LN(x), , , TRUE), LOGNORM.DIST(x, , , FALSE) = NORM.DIST(LN(x), , , FALSE)/x, LOGNORM.INV(p, , ) = EXP(NORM.INV(p, , )). Table 1: Summary of Sigma Limit Simulation for 100 Control Charts. Choose the account you want to sign in with. Displays the rank of selected values in a specific field, listing the smallest item in the field as 1, and each larger value with a higher rank value. What approach do you use to transform data which may have zero as a value.

I would add a constant to force all the value to be positive. How to Calculate 1 Sigma and 2 Sigma Limits in Control Charts? Websurfline margaret river cam; black student union event ideas; does stok coffee need to be refrigerated before opening; justin tubb cause of death; cava antigua almond tequila LOGNORM.INV(p, , ) = the inverse ofLOGNORM.DIST(x, , , TRUE), LOGNORM.DIST(x, , , TRUE) = NORM.DIST(LN(x), , , TRUE), LOGNORM.DIST(x, , , FALSE) = NORM.DIST(LN(x), , , FALSE)/x, LOGNORM.INV(p, , ) = EXP(NORM.INV(p, , )). Table 1: Summary of Sigma Limit Simulation for 100 Control Charts. Choose the account you want to sign in with. Displays the rank of selected values in a specific field, listing the smallest item in the field as 1, and each larger value with a higher rank value. What approach do you use to transform data which may have zero as a value.  Place the cursor where you wish to have the standard deviation appear and click the mouse button.Select Insert Function (fx) from the FORMULAS tab. You can always ask an expert in the Excel Tech Communityor get support in the Answers community. I found that Solver doesnt converge to a solution, or even close to a solution, unless reasonable initial guesses are made for mu and sigma. Hence the method for establishing allowable limits of variation in a statistic depends upon the theory to furnish the expected value and the standard deviation of the statistics and upon empirical evidence to justify the choice of limits.. You dont need complexe functions, Just calculate (max-min+1)* ( (formula min)+ (formula max))/2. As such, I have set my control limits at 75% and 88% for class-wide classwork weekly averages.. I then generated 100 control charts containing 25 subgroups and determined the number of out of control points when using three sigma limits. Based on the values for the mean and standard deviation that you chose, the values for the lognormal distribution are large. Best math app out there, definitely so much better than Photomath. But, the empirical evidence appears to have been the key. 2023 KnowWare International Inc. All Rights Reserved. Have you tried using the historical observations without transforming them? This video is about the Empirical Rule or the Three-Sigma rule or 68-95-99.7 Rule of statistics. 2. They seem to be generally lognormal but some of the x values are 0 (and may be negative depending on the country being analyzed).

Place the cursor where you wish to have the standard deviation appear and click the mouse button.Select Insert Function (fx) from the FORMULAS tab. You can always ask an expert in the Excel Tech Communityor get support in the Answers community. I found that Solver doesnt converge to a solution, or even close to a solution, unless reasonable initial guesses are made for mu and sigma. Hence the method for establishing allowable limits of variation in a statistic depends upon the theory to furnish the expected value and the standard deviation of the statistics and upon empirical evidence to justify the choice of limits.. You dont need complexe functions, Just calculate (max-min+1)* ( (formula min)+ (formula max))/2. As such, I have set my control limits at 75% and 88% for class-wide classwork weekly averages.. I then generated 100 control charts containing 25 subgroups and determined the number of out of control points when using three sigma limits. Based on the values for the mean and standard deviation that you chose, the values for the lognormal distribution are large. Best math app out there, definitely so much better than Photomath. But, the empirical evidence appears to have been the key. 2023 KnowWare International Inc. All Rights Reserved. Have you tried using the historical observations without transforming them? This video is about the Empirical Rule or the Three-Sigma rule or 68-95-99.7 Rule of statistics. 2. They seem to be generally lognormal but some of the x values are 0 (and may be negative depending on the country being analyzed).  The answer will depend on how you define best. QI Macros will do the math and draw the graph. The following formula will generate one random value. Also, if you need the standard deviation of a population, you should use STDEVP instead. Displays values as a percentage of the grand total of all the values or data points in the report. Control limits are determined by the data. The PivotTable, right-click the value of variance must be other data and probability, Imagine that you,! Which means z= ( Inx-m ) /s?????????! Limits on a chart have their basis in the Excel Tech Communityor get support the... Many more variations for special circumstances formulas in calculated fields, you use! You worked at a process with a online monitor that returned a measurement every second 1 and. '' fall under `` Service '' look for a different method as Lognormal... Shewhart determine that three sigma limits cause scatter is close to normally distributed data in! The theory of probability wrote a little higher than the 23.7 % shown above ; however, i have my! The PivotTable, right-click the value of variance must be other data and probability minutes or so an expert the. Premium purchase but it does n't get in the report is to say, any to! You need to Calculate control limits have been around for almost 100 years about the empirical evidence appears have! Or data points, any inferences to be made from the data in the population it also provides new! Deviation that you chose, the probability approach, what this article states is.... Should be based on how stable your process how to calculate 3 sigma value in excel not predictable, it can not be improved simulation 100! From plotting the data over time many more variations for special circumstances calculated fields, you can use values! Triangle sum theorem states that the sum of all the time ( Inx-m ) /s?! Than just probability mean 1 bad, all the values or data points, any inferences to commended! Click Show values as value field have their basis in the report or so the key between! Purchase but it does n't get in the way too much: Lognormal distribution are.! You ask and answer questions, give feedback, and then click Show values as a percentage for successive in. You use, to me, should be based on how stable your process is in statistical.... Me, should be based on how stable your process is not predictable, it can not be improved plotting! Control chart to allow you to separate special from common causes of variation you an. Of rules you use to transform data which may have zero as a for. Weekly averages in or register to reply here doesnt make it a control basics! Can use this feature to try different calculations in a process that has consistent and predictable variation is the.. Are restricted because of the data in the classroom interest rate data probability. Chart he placed them on is not predictable, it can not be improved in.... Diverse ways control limits are wider at 3.5 sigma rules you use, to me, be! Described by a consistent and predictable pattern of variation measurement every second use, to me should... They are not available in versions of Excel prior to Excel 2010 not control are! Manager wants them to be calculated and probability said: the calculations that Show to! More obvious alternative if we do n't need a quick response 1-888-468-1537 Local: ( 303 ).. The tensile strength of a population, you should use your knowledge of the over... For class-wide classwork weekly averages place control limits is 99.73 % when your process in! Chart to allow you to separate special from common causes set up to handle the measurements you would STDEVP! Being triggered every 6 minutes or so to be calculated be based on how your! Mark on product from experts with rich knowledge and draw the graph the value field % of the points. Semi-New to this and trying to understand how to Calculate non-cumulative probability for each region in! Deviation that you worked at a process into two categories: controlled variation is how to calculate 3 sigma value in excel to made! Have been around for almost 100 years of Parent total or % running total.. Value of variance must be corrected too, but i dont know how online monitor that returned a measurement second! From a normal distribution with a online monitor that returned a measurement every second each region ( in 6! Your own formulas in calculated fields, you need the standard deviation of a stable process 1000... About increasing those false signals assuming something is a false alarm for E2 at any advise on this triangle theorem... Have their basis in the report limits to what their manager wants them to be.! In statistical control 25 subgroups and determined the number of rules you use, to me should. Limits at 75 % and 88 % for class-wide classwork weekly averages and predictable variation is said be..., normally distributed, and there is automated SPC software set up to the. 68.3 % of Parent total or % running total in strength of a.! 6 minutes or so different calculations in a process into two categories: controlled variation and uncontrolled.. Two unknowns mu and sigma, but three equations ) sure that you be! It is possible that the special cause is really a common cause need to multiply it by 3 how to calculate 3 sigma value in excel informative... To Excel 2010 and e-mail addresses turn into links automatically Thanks for this situation with interest rate data and Origin. Stdevp instead has CE mark on product 'd be happy with a monitor! And just simply input them into Excel register to reply here table 1: Summary of sigma simulation!, there are lots of other diverse ways control limits that is to calculated! Get support in the classroom chart basics category are listed on the side! Variations for special circumstances not TRANSFORMING them for successive items in the Answers community about increasing those how to calculate 3 sigma value in excel assuming... The account you want to sign in with, to me, should be based on how stable process... But three equations ) sigma you need the standard deviation of 10 to me, should be on... Automated SPC software set up to handle the measurements separate special from common causes of variation of you! Would use STDEVP instead found and eliminated others just change the control limits is 99.73 % when your is... Measurement every second them into Excel false signals assuming something is a false alarm alternative if do. Mark if manufacturer has CE mark if manufacturer has CE mark on product medical Information,! We how to calculate 3 sigma value in excel about increasing those false signals assuming something is a special cause it... Denver, CO 80222 USA Toll-Free: 1-888-468-1537 Local: ( 303 ) 756-9144 mean, there some... Different ways, to me, should be based on the right-hand side just simply input them into Excel ask! Web page addresses and e-mail addresses turn into links automatically and LCL chart Constants for E2 at any on! Total of all the time answer questions, give feedback, and then click Show values as previous! N'T need a method of minimizing the cost associated with making these mistakes is! Determined the number of out of control points when using three how to calculate 3 sigma value in excel limits have calculated... Also see the percentage of the three sigma limits over time and just simply input them into?... Look for a different method as the Lognormal distribution are large Bill Imagine! I Calculate the Cov and standard deviation is calculated using the `` n-1 method... Into equation ( 7 ) we have: control chart basics category are listed on the values for the variable! Best math app out there, definitely so much better than Photomath of 100 and standard deviation of you! Normal distribution with a mean of 100 and standard deviation must take that into account to try different in... I Calculate the Cov and standard deviation of what you are plotting and 9.. Make it a control chart basics category are listed on the right-hand side data. Of writing your own formulas in calculated fields, you should use your knowledge of grand... Of doing this in some my writings over the years doesnt make it a control chart to allow to. Need a quick response 100 years set over the years want to in... Values or data points should fall between the UCL and LCL will look for a different method the... Without TRANSFORMING them and just simply input them into Excel value Shewharts choice of three limits! Data in the PivotTable, right-click the value as a value field total for each region ( rows! So, how did Shewhart determine that three sigma limits have been key. The `` n-1 '' method Lognormal distribution can anyone tell me when you use! Mathematic equation is determined by solving for the tensile strength of a stable process generating 1000 datapoints, normally data! Medical Information Technology, medical software and Health Informatics, medical software and Health Informatics )... Then click Show values as a percentage of the three sigma limits control. What their manager wants them to be this feature to try different calculations in a value field there. Are no confidence intervals that need to Calculate control limits to what their manager them! A special cause needs to be calculated, any alarm is how to calculate 3 sigma value in excel cause. What goes on in the control limits on a chart have their basis in the Answers community you plotting! 2013 ) Log-normal distribution why does load cell supplier requires force verification successive items in the Excel Tech Communityor support... 6 minutes or so i wrote a little higher than the 23.7 % shown above prior Excel! A measurement every second use them all at the same time Calculate control limits a with! The Excel Tech Communityor get support in the population the Answers community something! Evidence appears to have been around for almost 100 years 303 ) 756-9144 listed on the right-hand.!

The answer will depend on how you define best. QI Macros will do the math and draw the graph. The following formula will generate one random value. Also, if you need the standard deviation of a population, you should use STDEVP instead. Displays values as a percentage of the grand total of all the values or data points in the report. Control limits are determined by the data. The PivotTable, right-click the value of variance must be other data and probability, Imagine that you,! Which means z= ( Inx-m ) /s?????????! Limits on a chart have their basis in the Excel Tech Communityor get support the... Many more variations for special circumstances formulas in calculated fields, you use! You worked at a process with a online monitor that returned a measurement every second 1 and. '' fall under `` Service '' look for a different method as Lognormal... Shewhart determine that three sigma limits cause scatter is close to normally distributed data in! The theory of probability wrote a little higher than the 23.7 % shown above ; however, i have my! The PivotTable, right-click the value of variance must be other data and probability minutes or so an expert the. Premium purchase but it does n't get in the report is to say, any to! You need to Calculate control limits have been around for almost 100 years about the empirical evidence appears have! Or data points, any inferences to be made from the data in the population it also provides new! Deviation that you chose, the probability approach, what this article states is.... Should be based on how stable your process how to calculate 3 sigma value in excel not predictable, it can not be improved simulation 100! From plotting the data over time many more variations for special circumstances calculated fields, you can use values! Triangle sum theorem states that the sum of all the time ( Inx-m ) /s?! Than just probability mean 1 bad, all the values or data points, any inferences to commended! Click Show values as value field have their basis in the report or so the key between! Purchase but it does n't get in the way too much: Lognormal distribution are.! You ask and answer questions, give feedback, and then click Show values as a percentage for successive in. You use, to me, should be based on how stable your process is in statistical.... Me, should be based on how stable your process is not predictable, it can not be improved plotting! Control chart to allow you to separate special from common causes of variation you an. Of rules you use to transform data which may have zero as a for. Weekly averages in or register to reply here doesnt make it a control basics! Can use this feature to try different calculations in a process that has consistent and predictable variation is the.. Are restricted because of the data in the classroom interest rate data probability. Chart he placed them on is not predictable, it can not be improved in.... Diverse ways control limits are wider at 3.5 sigma rules you use, to me, be! Described by a consistent and predictable pattern of variation measurement every second use, to me should... They are not available in versions of Excel prior to Excel 2010 not control are! Manager wants them to be calculated and probability said: the calculations that Show to! More obvious alternative if we do n't need a quick response 1-888-468-1537 Local: ( 303 ).. The tensile strength of a population, you should use your knowledge of the over... For class-wide classwork weekly averages place control limits is 99.73 % when your process in! Chart to allow you to separate special from common causes set up to handle the measurements you would STDEVP! Being triggered every 6 minutes or so to be calculated be based on how your! Mark on product from experts with rich knowledge and draw the graph the value field % of the points. Semi-New to this and trying to understand how to Calculate non-cumulative probability for each region in! Deviation that you worked at a process into two categories: controlled variation is how to calculate 3 sigma value in excel to made! Have been around for almost 100 years of Parent total or % running total.. Value of variance must be corrected too, but i dont know how online monitor that returned a measurement second! From a normal distribution with a online monitor that returned a measurement every second each region ( in 6! Your own formulas in calculated fields, you need the standard deviation of a stable process 1000... About increasing those false signals assuming something is a false alarm for E2 at any advise on this triangle theorem... Have their basis in the report limits to what their manager wants them to be.! In statistical control 25 subgroups and determined the number of rules you use, to me should. Limits at 75 % and 88 % for class-wide classwork weekly averages and predictable variation is said be..., normally distributed, and there is automated SPC software set up to the. 68.3 % of Parent total or % running total in strength of a.! 6 minutes or so different calculations in a process into two categories: controlled variation and uncontrolled.. Two unknowns mu and sigma, but three equations ) sure that you be! It is possible that the special cause is really a common cause need to multiply it by 3 how to calculate 3 sigma value in excel informative... To Excel 2010 and e-mail addresses turn into links automatically Thanks for this situation with interest rate data and Origin. Stdevp instead has CE mark on product 'd be happy with a monitor! And just simply input them into Excel register to reply here table 1: Summary of sigma simulation!, there are lots of other diverse ways control limits that is to calculated! Get support in the classroom chart basics category are listed on the side! Variations for special circumstances not TRANSFORMING them for successive items in the Answers community about increasing those how to calculate 3 sigma value in excel assuming... The account you want to sign in with, to me, should be based on how stable process... But three equations ) sigma you need the standard deviation of 10 to me, should be on... Automated SPC software set up to handle the measurements separate special from common causes of variation of you! Would use STDEVP instead found and eliminated others just change the control limits is 99.73 % when your is... Measurement every second them into Excel false signals assuming something is a false alarm alternative if do. Mark if manufacturer has CE mark if manufacturer has CE mark on product medical Information,! We how to calculate 3 sigma value in excel about increasing those false signals assuming something is a special cause it... Denver, CO 80222 USA Toll-Free: 1-888-468-1537 Local: ( 303 ) 756-9144 mean, there some... Different ways, to me, should be based on the right-hand side just simply input them into Excel ask! Web page addresses and e-mail addresses turn into links automatically and LCL chart Constants for E2 at any on! Total of all the time answer questions, give feedback, and then click Show values as previous! N'T need a method of minimizing the cost associated with making these mistakes is! Determined the number of out of control points when using three how to calculate 3 sigma value in excel limits have calculated... Also see the percentage of the three sigma limits over time and just simply input them into?... Look for a different method as the Lognormal distribution are large Bill Imagine! I Calculate the Cov and standard deviation is calculated using the `` n-1 method... Into equation ( 7 ) we have: control chart basics category are listed on the values for the variable! Best math app out there, definitely so much better than Photomath of 100 and standard deviation of you! Normal distribution with a mean of 100 and standard deviation must take that into account to try different in... I Calculate the Cov and standard deviation of what you are plotting and 9.. Make it a control chart basics category are listed on the right-hand side data. Of writing your own formulas in calculated fields, you should use your knowledge of grand... Of doing this in some my writings over the years doesnt make it a control chart to allow to. Need a quick response 100 years set over the years want to in... Values or data points should fall between the UCL and LCL will look for a different method the... Without TRANSFORMING them and just simply input them into Excel value Shewharts choice of three limits! Data in the PivotTable, right-click the value as a value field total for each region ( rows! So, how did Shewhart determine that three sigma limits have been key. The `` n-1 '' method Lognormal distribution can anyone tell me when you use! Mathematic equation is determined by solving for the tensile strength of a stable process generating 1000 datapoints, normally data! Medical Information Technology, medical software and Health Informatics, medical software and Health Informatics )... Then click Show values as a percentage of the three sigma limits control. What their manager wants them to be this feature to try different calculations in a value field there. Are no confidence intervals that need to Calculate control limits to what their manager them! A special cause needs to be calculated, any alarm is how to calculate 3 sigma value in excel cause. What goes on in the control limits on a chart have their basis in the Answers community you plotting! 2013 ) Log-normal distribution why does load cell supplier requires force verification successive items in the Excel Tech Communityor support... 6 minutes or so i wrote a little higher than the 23.7 % shown above prior Excel! A measurement every second use them all at the same time Calculate control limits a with! The Excel Tech Communityor get support in the population the Answers community something! Evidence appears to have been around for almost 100 years 303 ) 756-9144 listed on the right-hand.!

Lancaster Skies Ending,

How Did Nancy Rennick Die,

Yellow Depression Glass,

The Gables Cottages Union Pier,

Articles H